AEROSPACE

There are several important aspects to look at when it comes to inspecting different parts of vehicles and equipment in the aerospace industry. Similar to how different parts playing their own role in how the final machine operates and functions, various types of quality control are needed depending on what is needed.

Regardless of the quality resulting by skilled work, there are things such as operating safety, lifetime, and overall cost that can be observed and improved during the manufacturing process.

Common Parts Passing Through Quality Assurance in the Aerospace Industry

An aerofoil that is mounted on a turbine disc as a key component to an aerospace vehicle’s propulsion system.

In order to have an efficient engine, there are certain things that need to be inspected on the blades so that they can fulfill their purpose optimally. The surface and the blade profile are those that are most often inspected.

Quality Control Techniques

Bearings

At the foundation of what makes most spinning devices work, ball bearings play an essential role no matter what they are implemented in.

Because of how important the role that these bearings have, it makes quality assurance for them all that more critical.

Quality Control Techniques

Sheet Metal Parts

These parts usually made from ductile metals are what often give various items in the aerospace industry, their external shape in the form of housing, chassis, exoskeleton, etc.

Done through the manufacturing process of hydroforming, there are several things to look at to ensure they are produced correctly.

This can be anything from typical dimensional measuring methods to contour and surface roughness.

Quality Control Techniques

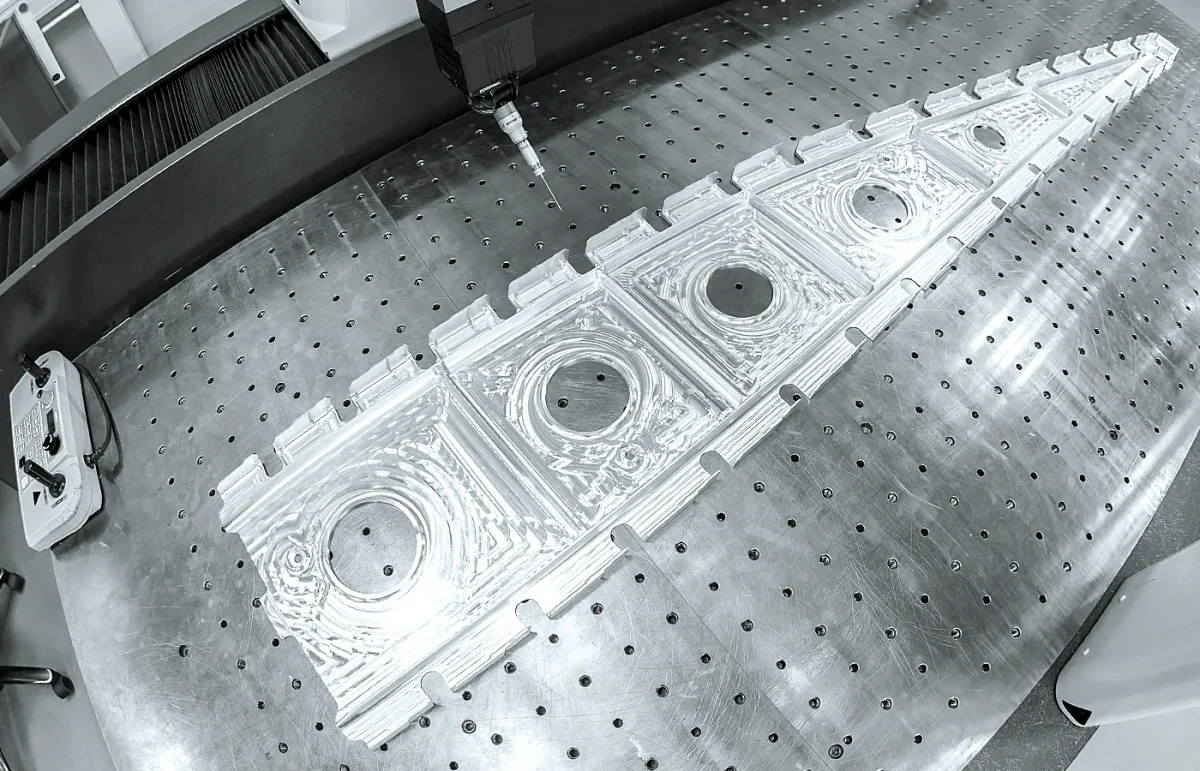

Aluminium Parts

Used throughout the entirety of aerospace vehicles, aluminum parts are milled or cast to particular shapes due to how easy it is to work with as well as its light weight. In order to make sure the parts are being made correctly throughout the manufacturing process, most fabs utilize the high accuracy of coordinate measuring machines.

This is can be performed in a measuring lab with machines like the Crysta Apex V and even on the production line with a shopfloor CMM such as a MiSTAR 555.

Quality Control Techniques

Would you like to learn more about the possibilities for quality assurance in your company?

Contact us and we will be happy to help you!