M³ Solution

M³ Solution

Special measurement technology - Automation - Loading systems

Quality Data Systems

Quality Data Systems

QDS Hardware and Software

Styli

Styli

Probes from KOMEG - Perfection for your Quality Assurance

Fixture Systems

Fixture Systems

Standard fixture systems - for measurably better results

Special Solutions

Special Solutions

To get an overview of KOMEG's capabilities, our collection of individual special solutions is particularly useful.

Career

Career

Learn more about KOMEG as an employer and how you can start your career with us!

Contact persons

Contact persons

You have questions or need more information? We are happy to help you!

Discover Mitutoyo

Discover Mitutoyo

The world's biggest metrology company

Aerospace

Aerospace

Complex aerospace applications need fast, extremely precise quality control to ensure accurate assemblies. See how Mitutoyo makes it happen

Automotive

Automotive

The automotive industry continues to innovate, and Mitutoyo delivers the advanced inspection and scanning capabilities to help manufacturers achieve ongoing production

Energy

Energy

Our measurement and analysis solutions are designed to help energy providers improve reliability and increase equipment uptime.

Medical

Medical

To protect patient well-being, medical applications require exceptional accuracy. Learn how extensively tested solutions from us can help you do just that.

General Manufacturing

General Manufacturing

Ensure high repeatability and strict quality control with form measuring solutions, coordinate measuring machines and precision measuring machines from us.

Electro

Electro

Our non-contact and optical measurement solutions bring microscopic accuracy to smaller and denser electronic components.

Special Solutions

Special Solutions

To get an overview of KOMEG's capabilities, our collection of individual special solutions is particularly useful.

Product Literature

Product Literature

Sehen Sie sich unseren Katalog, unsere Produktbroschüren und mehr an und laden Sie sie herunter.

Mitutoyo Online Katalog

Mitutoyo Online Katalog

Sehen Sie sichdas umfangreiche Sortiment von Mitutoyo im Online-Katalog an!

-

Products

- Back Products

- Products

-

M³ Solution

- Back M³ Solution

- M³ Solution

-

Quality Data Systems

- Back Quality Data Systems

- Quality Data Systems

- Styli

-

Fixture Systems

- Back Fixture Systems

- Fixture Systems

-

Special Solutions

- Back Special Solutions

- Special Solutions

-

About us

- Back About us

- About us

-

KOMEG

- Back KOMEG

- KOMEG

-

Learn more about KOMEG

- Back Learn more about KOMEG

- Learn more about KOMEG

-

Certifications and accreditations

- Back Certifications and accreditations

- Certifications and accreditations

- Career

-

Contact persons

- Back Contact persons

- Contact persons

-

Discover Mitutoyo

- Back Discover Mitutoyo

- Discover Mitutoyo

-

Name & Philosophy

- Back Name & Philosophy

- Name & Philosophy

-

Mitutoyo Corporation

- Back Mitutoyo Corporation

- Mitutoyo Corporation

-

Mitutoyo in Europe

- Back Mitutoyo in Europe

- Mitutoyo in Europe

-

Products Legitimacy (FAKE)

- Back Products Legitimacy (FAKE)

- Products Legitimacy (FAKE)

-

Industries

- Back Industries

- Industries

- Aerospace

-

Automotive

- Back Automotive

- Automotive

- Energy

- Medical

-

General Manufacturing

- Back General Manufacturing

- General Manufacturing

- Electro

-

Special Solutions

- Back Special Solutions

- Special Solutions

-

Modification Micrometer 422-230-30

- Back Modification Micrometer 422-230-30

- Modification Micrometer 422-230-30

-

Downloads

- Back Downloads

- Downloads

-

Product Literature

- Back Product Literature

- Product Literature

-

Mitutoyo Online Katalog

- Back Mitutoyo Online Katalog

- Mitutoyo Online Katalog

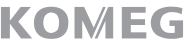

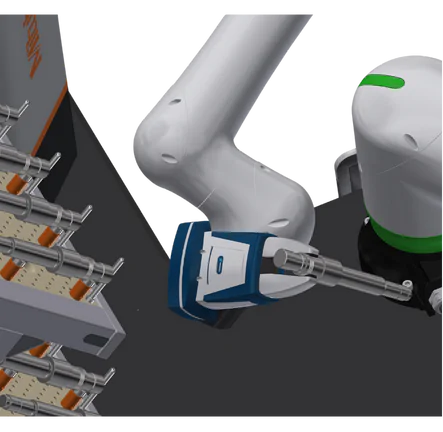

Automated loading system for the Roundtracer Flash

An automated loading system was developed here.

The robot arm from Fanuc removes a workpiece from a shelving system and clamps it onto the "Roundtracer Flash" (RTF) form measuring device for measurement. After the measuring process, the workpiece is put back, the next workpiece is removed and clamped onto the RTF for measurement.

For this purpose, 2 tables were coupled and the RTF was firmly connected to the table.

The racking system was constructed from Mitutoyo eco-fix modules. The robot is a so-called COBOT (collaborative robot), which does not require a special protective housing for operation and the gripper from Schunk is also collaborative. The system was programmed by Mitutoyo.

Do you have any questions about the product or would you like to find out more about our customised solutions?

Contact us and we will be happy to help you!